About

Six decades of innovation and excellence in air bearing technology and dicing machinery.

Loadpoint has a fascinating and complex history which reflects the products and machines we manufacture. We are proud of our heritage especially as we are unique within British manufacturing. We have two arms to the business but we are very much one family.

Our manufacturing site in Cricklade, Wiltshire is the hub for our dicing solutions. This includes manufacturing dicing machines and sub-contract dicing services primarily for the for the semi-conductor industry. We are the only remaining manufacturer of these dicing machines in the UK and the high specification air bearing spindle technology, a critical component of precision cutting of wafers, are tried and tested on site.

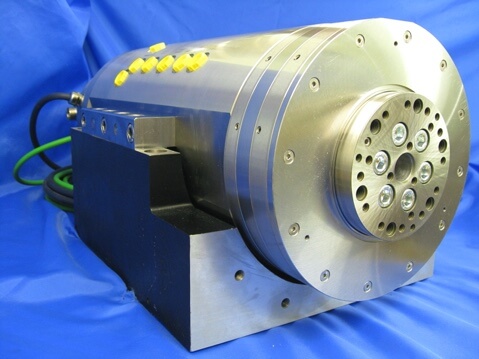

In Ferndown, Dorset we design, engineer and manufacture all in-house the air bearing spindles. Although this sounds more straightforward the level of quality and accuracy required to produce these parts is paramount. We like to say our customers measure us in nanometers! All parts are manufactured on-site from Steel, aluminum and bronze billets and are then assembled, tested and certified to the high specifications required by our global customers.

Synergy and collaboration between the two sites are of paramount importance due the ongoing innovation required by the global industries we serve. If you are interested to find out more about our company or the services we offer please contact us today

Our Values

Loadpoint Early History

-

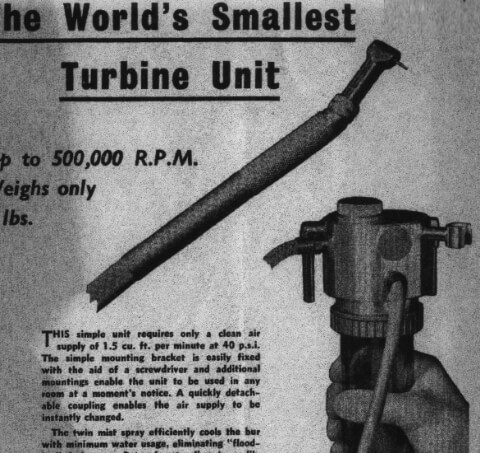

1959The inception of Air-Bearing SpindleIn 1959 Nigel Allen started a company called Micro Turbines Ltd based in Hertfordshire and set about putting his new dental spindle into production.

1959The inception of Air-Bearing SpindleIn 1959 Nigel Allen started a company called Micro Turbines Ltd based in Hertfordshire and set about putting his new dental spindle into production.

The final design of the dental ball bearing drill consisted of the ball bearing spindle with a control block, a water bottle, a hand piece and lead, a foot control and mounting bracket. It only required clean air of 40psi to run it and this is where the air bearing was first born. -

1965Westwind TurbinesBy 1965 Westwind Developments had become Westwind Turbines and was situated in a large factory in Dorset. The years from 1962 to 1965 had been used to develop manufacturing techniques required to produce industrial air bearing spindles. It was during this time that two of Loadpoint Bearings founding fathers would get together and start work with Nigel Allen.

-

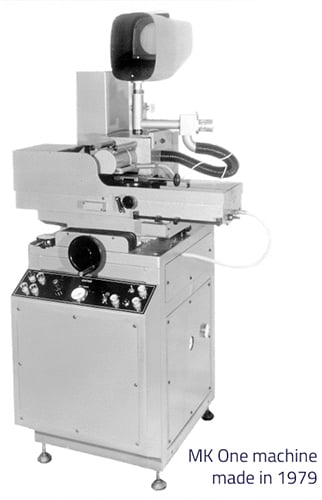

1968Wafer dicing innovationIn the late 60s, Loadpoint (originally ‘Semitron’) was the first company to pioneer the use of air bearing spindles for dicing silicon wafers and ceramic components. This arose from the need to increase cut quality and productivity in their own zenor-diode manufacturing facility. At the time, scribe and break was the standard method for cutting silicon. Semitron pioneered the technology of using a diamond abrasive wheels to grind through the silicon, which instantly became the preferred methodology.

-

1977The company journey beginsStarting a new company needs several things. An idea, time, money, people, premises, machinery and a company name.

The idea was already there and the money came from a £75,000 loan from the Co-op bank.

Nigel already had Ron Woolley on board. He also heard his old colleague Peter Fraser was unhappy at Westwind. The last “Founding Father” was Roger Martin who was also working at Westwind. Loadpoint Bearings was born ...

Nigel Allen, Peter Fraser, Roger Martin and Ron Woolley. -

1979Factory construction 1979

1979Factory construction 1979 -

1980'sLoadpoint formed following the sale of the Semitron semiconductor division in the early 1980s. Loadpoint has become well-known and respected for service and quality of products around the world.

1980'sLoadpoint formed following the sale of the Semitron semiconductor division in the early 1980s. Loadpoint has become well-known and respected for service and quality of products around the world. -

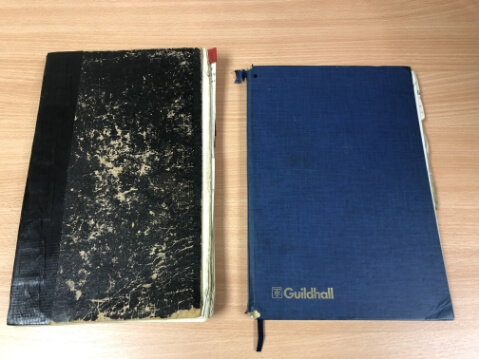

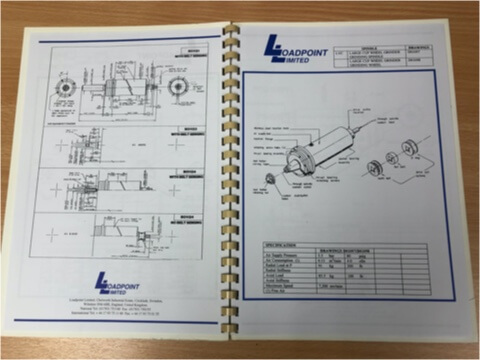

1980sThe original spindle test result books

1980sThe original spindle test result books -

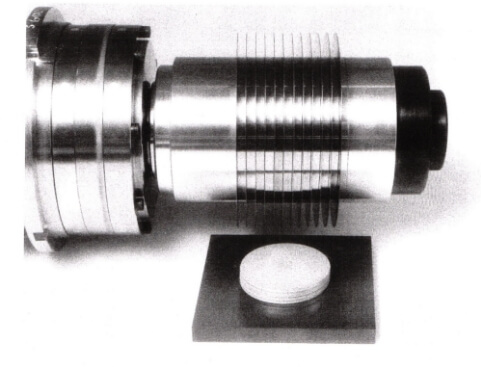

1980sLRM7 Spindle with multiple blades. This is gang blade dicing

1980sLRM7 Spindle with multiple blades. This is gang blade dicing -

Loadpoint Bearings factory October 1985

Loadpoint Bearings factory October 1985 -

1980sThough owned by Brammer since 1983 it was not until September 1985 that the company name was changed from Precision Rotors (Dorset) Ltd to Pope Precision Rotors Ltd. Over the years I have been asked many times what the company was like to work for in the 1980s. It was fun. A time of opportunity for the company and I really enjoyed it. At the time there were no smartphones, and almost no talking on the shop floor. The only noise was a noisy old compressor and the cuts on the machines. Althougheven with new technology, if you were on the shop floor now and were transported back to that time, many of the jobs being done then were done exactly the same as they are today.

-

Loadpoint Bearings factory October 1985

Loadpoint Bearings factory October 1985 -

1980sDesign of Aerostatic Bearings book

1980sDesign of Aerostatic Bearings book -

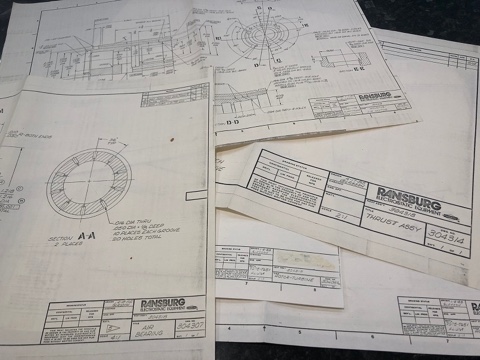

1985The original Ransburg drawings

1985The original Ransburg drawings -

1990

The 90s was a decade when we were joined by the people who were to take company forward.

In April 1990 Pope Precision Rotors Ltd was sold to Loadpoint Ltd and the name changed to Loadpoint Bearings Ltd. -

1993Front room with drawing board. Note the drawings stuck on the wall

1993Front room with drawing board. Note the drawings stuck on the wall -

1994One of our longest serving employees, Geoff Mair on the Tacchella grinding machine

1994One of our longest serving employees, Geoff Mair on the Tacchella grinding machine -

1994Bernard Harvey on the Colchester lathe

1994Bernard Harvey on the Colchester lathe -

1994David Gilham in front of Loadpoint Bearings first computer

1994David Gilham in front of Loadpoint Bearings first computer -

1995Dr Frank Wardle and Mr Sweet

1995Dr Frank Wardle and Mr Sweet -

1997Jason Brailey using AutoCAD 14

1997Jason Brailey using AutoCAD 14 -

1998Loadpoint Ltd Catalogue

1998Loadpoint Ltd Catalogue -

2000sTaylor Hobson D04982 NanoSteel spindle

2000sTaylor Hobson D04982 NanoSteel spindle -

.webp) 2000Mr Sweet with the Tetraform C

2000Mr Sweet with the Tetraform C