Industries We Help

As pioneers in air bearing technology and dicing solutions, we lead the way in helping businesses realise their full potential, this has primarily been focused in the Semi-Conductor industry. However, use of this advanced technology has spread into several other industries for specific applications. Some examples are below.

From the intricate needs of electronics and ICT to the complex yet robust demands of aerospace and space exploration. We have contributed to advances in medical, optical, space, defence, automotive, and sensing and control sectors. If you require highly advanced precision cutting and grinding technologies especially for clean manufacturing environments then please contact us

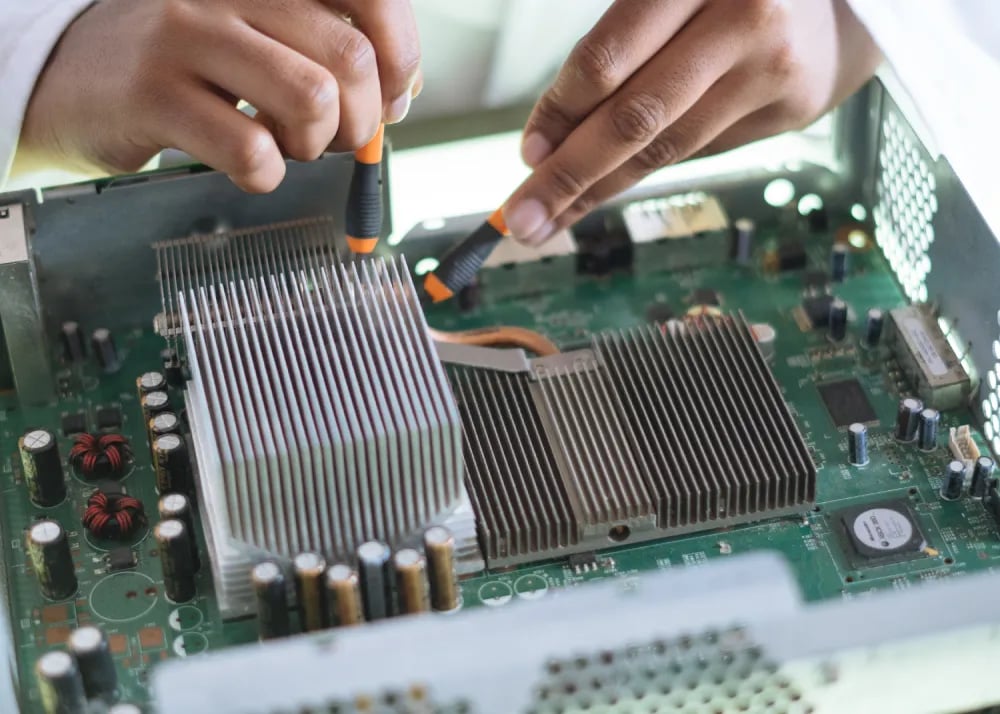

Semiconductors

Semiconductors are the backbone of the modern digital era, playing a pivotal role in the functionality of a variety of electronic devices. Loadpoint are proud of their contribution to cutting-edge techniques and technologies that bring this incredible microtechnology to life.

Our expertise spans processes such as dicing, a precise method of cutting semiconductor wafers into individual die; grinding, which refines the surface and thickness of the wafers; singulation, the isolation of individual chips from a larger wafer; and core drilling, a specialised approach to creating precise holes.

Optical

In the world of optics, Loadpoint sets the standard as a leader in precision and innovation. Our expertise in dicing technology extends seamlessly into the realm of optical materials and components.

From crafting delicate lens arrays to processing advanced optical fibres and waveguides, our capabilities are at the leading edge of precision and efficiency.

With Loadpoint as a partner, you can anticipate solutions that push the boundaries of optical clarity, reliability, and performance.

Automotive

An critical part of automotive production is the final finishing. This is where air-bearing technology is utilised used in a rotary atomiser turbine for the painting and coating.

This highly specialised industry process requires using the highest quality spindles and air bearings together with the bell assembly. These components are designed to withstand continuous industrial operation at the highest possible level.

Loadpoint Insights

Loadpoint Debuts at LASER World of PHOTONICS CHINA!

Loadpoint Shines at the 50th Annual EFCLIN Congress and Exhibition

Metrology

In this sector precision is everything. Loadpoint, with its deep-rooted mastery in dicing technology, is uniquely positioned to cater to the intricate demands of metrological applications.

Our abilities encompass the design and development of components that ensure complete accuracy, repeatability, and reliability.

With a keen understanding of measurement science and its critical role in industries worldwide, we employ state-of-the-art techniques and advanced materials to guarantee that every product meets and exceeds the strictest precision standards.