Specialist Spindles

We are a leading supplier of spindles to original equipment manufacturers in the ultra-precision machining industry

A range of spindles are available for applications including contact lens turning, flycutting of optical components, mould grinding and ultra precision face grinding. Spindle designs are continually reviewed and updated to include the latest innovations in high precision technology.

They are manufactured to the highest standards of precision. They are also fitted with low noise motors and are dynamically balanced to within 0.001 gm cm to achieve motion errors as low as 0.05 um peak-peak. Bearing designs are also optimised to give maximum overall spindle stiffness in both radial and axial directions.

They are manufactured to the highest standards of precision. They are also fitted with low noise motors and are dynamically balanced to within 0.001 gm cm to achieve motion errors as low as 0.05 um peak-peak. Bearing designs are also optimised to give maximum overall spindle stiffness in both radial and axial directions.

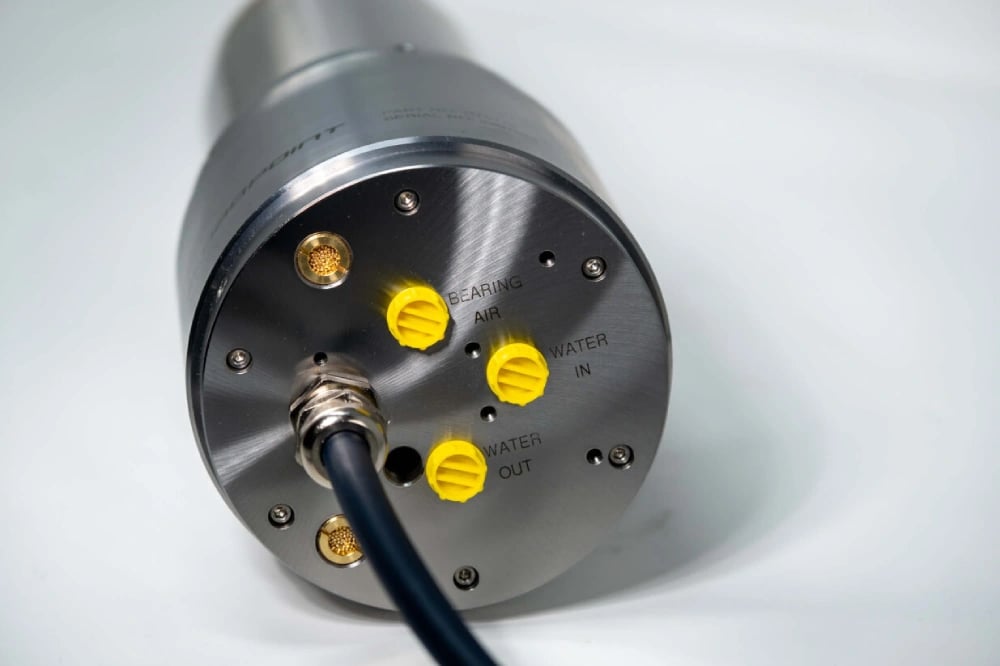

Spindles are available with foot mounted or plain cylindrical housings. Work or tool holding arrangements are manufactured to suit individual requirements and include air operated chucks, vacuum chucks and collets.

Smaller spindles within the range can reach speeds of 15 000 rpm with air cooling or 25 000 rpm with water cooling. These higher speed spindles are fitted with AC induction motors whilst spindles designed for lower speed machining applications are fitted with DC brushless motors. Encoders are used where accurate speed control or angular positioning is required.

Ultra precision spindles may also be integrated with air slides for applications requiring extreme positional accuracy.

Smaller spindles within the range can reach speeds of 15 000 rpm with air cooling or 25 000 rpm with water cooling. These higher speed spindles are fitted with AC induction motors whilst spindles designed for lower speed machining applications are fitted with DC brushless motors. Encoders are used where accurate speed control or angular positioning is required.

Ultra precision spindles may also be integrated with air slides for applications requiring extreme positional accuracy.

FAQs

Where are air bearing spindles used in machining?

Air bearing spindles are commonly used in applications requiring high precision and ultra-smooth rotation, such as in semiconductor manufacturing, optical lens grinding, and precision machining of components for aerospace and medical industries.

Can existing machines be upgraded with air bearing spindles?

Upgrading your existing machines with our air bearing spindles presents a transformative opportunity to elevate performance.

By making this upgrade, you invest in a solution that not only modernizes your equipment but also significantly boosts overall productivity and competitiveness in the market.

Consult with our team to explore how to optimize your specific machining requirements and deliver tangible performance improvements.